What is 'mixture' and why do I care?

For gasoline to burn it needs oxygen.

For the most complete combustion gasoline usually needs to be burned at a ratio of 14.7 parts of air to 1 part fuel. This air to fuel ratio (AFR) is called stoichiometric or Lambda = 1. This is just a ratio between air and fuel. For example all of the following are at the same AFR:

7.35 lbs of air to 0.5 lbs of fuel

14.7 lbs of air to 1 lbs of fuel

147 lbs of air to 10 lbs of fuel

Obviously the amount of air and fuel being burned is totally different between each example but the AFR for each is identical.

14.7:1 AFR is normally considered the best trade off between emissions, fuel economy and power production.

Running LEAN is when your AFR has more air to it. The AFR is greater then 14.7:1 (Lambda >1) for example 16:1 AFR is lean. Running lean increases emissions, increases heat, usually increases fuel economy, reduces power and increases the chances of knocking.

Running RICH is when your AFR has more fuel to it. The AFR is less then

14.7:1 (Lambda <1) for example 13:1 AFR is rich. Running rich increases

emissions, usually decreases heat, decreases fuel economy, increases power

(to a point), decreases the chance of knocking. Running rich for long periods

of time can cause deposits to build up on the plugs and O2 sensors (fouling)

and can clog your catalytic converter. Maximum power is usually obtained

running around a 12.3:1 AFR. Going richer then that will cost a little

power but you loose less power then being leaner then 12.3:1. This can

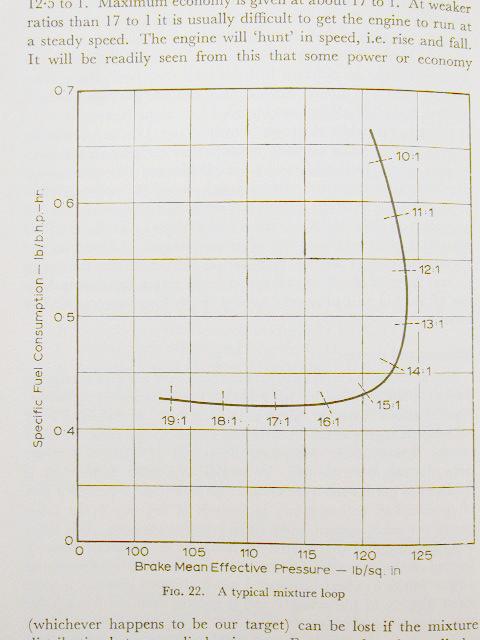

be seen in the graph below.

The above graph is taken from 'The Sports Car Engine: Its Tuning and Modification' by Colin Campbell. The graph shows basically how much pressure is created by burning gasoline at different AFRs and also how much fuel is consumed in doing so. Highest power will be achieved at highest pressure (most force pushing on your pistons).

When you are cruising and idling (the emissions cycle) the DME uses your oxygen sensors ( O2 sensors) to determine what AFR the engine is running at. The O2 sensors sense how much O2 is in the exhaust and send a voltage signal to the DME to give the mixture. Different manufacturers of O2 sensors send different voltage signals to the DMEs they are used with. However the DMEs logic behind the O2 sensor data is the same.

The DME will adjust the mixture so that the engine runs at 14.7:1 AFR under emissions cycle. Actually, what it does is 'dither' the mixture which is swing it rich to lean and back centered around 14.7:1 AFR. It does this as it is better for the catalytic converter. When the DME is using the O2 sensors feedback it is considered to be in 'closed loop' mode.

As the DME makes its adjustments to the mixture, called the short term fuel trim(STFT), it keeps an average of what adjustments it has made over time. That average is applied against something called the long term fuel trim (LTFT) and is the 'adaptation' that is always talked about. During closed loop operation BOTH the STFT and the LTFT have an effect on mixture.

For example say your have a car that its emission cycle mixture is roughly 5% rich. We clear the adaptation (LTFT= 0.0%) and take the car for a drive. What happens?

Once the car has warmed up and gone closed loop the DME will detect, using the O2 sensors, that the mixture is 5% rich. The STFT will equal -5%. That is the DME is reducing the fueling to the car by 5%. This results in the mixture being 14.7:1. At first the LTFT=0.0%. Over time the LTFT will slowly move negative.

As that occurs the STFT will move to be less negative because the LTFT is now also removing some of the extra fuel. So the correction needed by the STFT will be less.

After driving for awhile you could see the following:

LTFT= -1% STFT= -4%

then a little later

LTFT= -3% STFT= -2%

then a little later

LTFT= -5% STFT= 0%

If the conditions stay the same the car has 'finished' adapting. Because the STFT is now 0% adjustments to the LTFT will stop until STFT moves away from 0%.

In reality the STFT tends to move all over the place if you watch it while regularly driving which is why the DME slowly adjusts the LTFT based on what the STFT tends to be centered around.

The adaptation is important to understand because the long term trim is applied against your wide open throttle (WOT) fuel maps even though the DME does not use the O2 sensors at WOT. It is running 'open loop' (no O2 sensor feedback) when it is in the power cycle. During the power cycle the DMEs maps are programmed to intentionally run the engine somewhat richer in pursuit of more power. Aftermarket 'chips' tend to run WOT richer yet to try to extract maximum power.

If you mod your engine to run richer all the time, say by just putting in larger fuel injectors, then during the emissions cycle the DME is going to know it is running rich based on the O2 sensors feedback. It will adapt out the extra fuel, at first with the STFT then later more and more with the LTFT to get the mixture back to 14.7:1 to reduce emissions. Now when you go WOT the DME will stop using O2 sensors feedback but it will still remove however much fuel the LTFT tells it to. The net effect is that your mod to richen the mixture won't work after you have driven the car a little while. In fact it could lean you out depending upon how much fuel the LTFT removes.

This will work in reverse to. If you lean out your mixture during emissions cycle the DME will ADD fuel as needed to get back to a 14.7:1 AFR and this will be seen in the LTFT. It does this because running lean increases emissions which the DME doesn't want to do. Now when you go WOT the LTFT will add fuel.

If you make your emissions cycle mixture 'perfect' at AFR 14.7:1 then adaptation will NOT occur and it will have no effect at all on your WOT mixture.

Enough theory.... Lets figure out what your cars mixture is.

As mentioned above your O2 sensors just outputs a voltage to the DME to tell the mixture. To determine what your mixture is you basically just need to monitor that voltage and know how to interpret it. There are a bunch of options here.

The BEST and easiest way to do it is to use OBDII scanning software. Using this method you just plug into the OBDII port and log RPM and the O2 sensor at Bank 1 Sensor 1. Then in second or third gear starting at 1000 rpm run the car to redline at WOT. This will give you a very nice graph of your O2 voltage at various points over the rev band. If you are lean at only a specific point in the range this will show it to you easily. With the OBDII scanning software you can also watch your LTFT(s) to see what effect adaptation is having on your mixture.

Another option is to purchase one of the multitude of mixture meters on the market. These usually have colored LEDs in a line which tells you your mixture based on which LED lights up. They are basically voltmeters that light the LEDs based on the voltage encountered. For what most of these cost you could purchase OBDII scanning softare which will tell you far more info. But these can still be handy as they usually are permantly mounted in the car. They typically are wired into your first O2 sensor and into a source of switched 12v power and a ground. The problem with these is you can't get any sort of graph of your mixture. You just have to watch the road, RPM and the mixture meter all at once when doing a mixture run to see what and where the mixture is. If you have a camcorder video taping the meter and the tach would be a great idea for later analysis. A co-pilot would help too.

The last option is the cheapest. Since the O2 sensor is sending nothing but a voltage to the DME we can watch that voltage with a voltmeter and use it as a cheaper form of mixture meter. Unfortunatly, there isn't an easy access point for the O2 sensors voltage. We need to tap into the wiring for the pre-catalytic O2 sensor(s). We want the pre-cat sensor as the post-cat sensor is slower to respond to changes and shows a leaner mixture because of the action of the catalytic converter. On BMW six cyliners there are two pre-cat O2 sensors. Each one gives the mixture on three cylinders. Checking the mixture of each bank of cylinders is good to verify every your fuel distribution is even. Which it should be on a fuel injected car.

Basically you want to tap into the sensors signal line and the signal ground for best results. Consult a wiring diagram for you car on which wires you want to access. It might be handy to add a connector so you can tap into the wiring for a quick and easy test point later on.

For the voltage meter a really basic model is all that is needed. The voltages measured will either vary from 0-1v or 0-5 volts DC. An analog or digital model will work. If you have an analog model be sure it has a voltage scale similiar to what you are measuring so you can see the differences easiest. For a digital voltmeter you want a meter that you can manually set the voltage range. This will make it react to changes faster.

Basically you will do the same sort of run as using a 'real' mixture meter. Once again a cam-corder or a co-pilot recording voltages and RPM would be better and safer.

To make sense of any of this data you need to know what voltages your O2 sensor puts out and what they mean. This is pretty easy to figure out. With the car off and cold hook up your voltmeter and set it to 0-3v DC range or the next greatest range. Start the car and look at the voltage coming off the O2 sensor. You should see either 2.5v or 0.45 volts. What you are measuring is the bias voltage applied to the O2 sensor before it has warmed up enough to create its own voltages. This voltage point is where the cars AFR is 14.7:1 (Lambda=1). Think of it as a pivot point in the mixture. One side swings richer and richer, the other leaner and leaner.

If the voltage is 2.5v set your meters range to 0-5v. If it is 0.45v set your meter to 0-1v range or the closest range available. Remember this range as this is what you will use in the future.

After a few minutes the O2 sensor will warm up enough to start working. You will see this on the meter as the voltage will start moving around even when idling. This is the DME dithering the mixture as explained above. Now we need to determine which voltage direction is RICH and which is LEAN. It will vary depending upon the operating principal of your O2 sensors.

Take the car for a drive. During your cruising and light acceleration the voltages will continue to bounce above and below the pivot voltage While you (or a co-pilot) are watching the voltmeter floor the throttle. The voltage will move in either direction and be steady while you are at WOT. Note the direction it moves in and this is the rich side of the gauge. Totally take your foot of the gas but don't push in the clutch. While you are engine braking (above 2k or so) the engine will be extremely lean (fuel injectors are basically off) and you will see the voltage move to the opposite side of the range. This is the lean side of your gauge. You now have the basic info needed to watch your mixture across the RPM band @WOT and see where it is richer or leaner.

Hint: 1.9l Z3s (w/ Bosch O2 sensors) are 0-1v with 0.9-1v being rich (12.5:1ish AFR) and 0.0v being very lean. 0.45v is 14.7:1 AFR.

Siemens O2 sensors work opposite the Bosch sensors in that a low voltage signal is rich and a high voltage signal is lean.

Note that with none of the sensors can you have a negative voltage. If rich is below 0.45v (like on Siemens O2 sensors) it is possible to be running way to rich and be off the scale of the meter. Running that rich is wasting fuel and power. There is such a thing as too much fuel.

Breaking the voltage down to a specif AFR will depend upon the O2 sensors used. The types of sensors used in production vehicles are really best suited to determining 14.7:1 AFR. At the rich/lean limits they aren't as accurate. Still having this info is much better then having no idea what your mixture is. Be sure you check your mixture when your engine is fully warmed up. When the engine is cold or just starting to warm up the DME intentionally runs richer as part of its 'cold start routine.'

If you are stock getting this data is interesting but isn't nearly as important as if you are highly modified. Say for example you have added forced induction (turbo or supercharger) to your engine. Now having your mixture proper at WOT is critical. If you aren't rich enough you could easily be knocking. If you have knock sensors this will cause the DME to take out loads of ignition advance to get rid of the knock. This will take away a lot of power as well as being dangerous for your engine. This could be occuring and you might not even be aware of it as you won't hear any pinging or knock.

If the knock is bad enough (or you don't have knock sensors) you could tank your engine very quickly.

Getting the WOT mixture proper is essential on a forced induction engine. You want the mixture to be at least in the 12.x:1 AFR range (across the entire RPM band@WOT) and it would be safer to be even a little richer. The extra fuel will also help to cool the intake charge which will further reduce the chance of knocking. You don't want to be so rich that you are blowing black smoke though.

If you think you are having timing retard problems on a forced induction engine or that it just isn't pulling like it should up high checking your mixture is the first thing on the list. Even if you think the engine is running great watching your mixture is good peace of mind. Unless of course you find that your mixture is dropping off at high RPM..... then you start panicing on how to fix it.

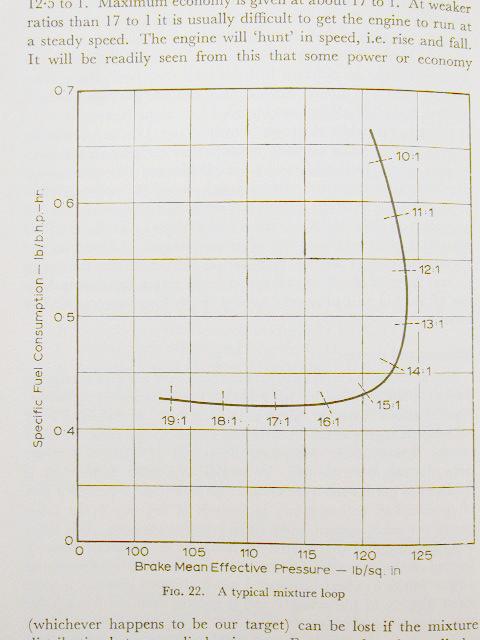

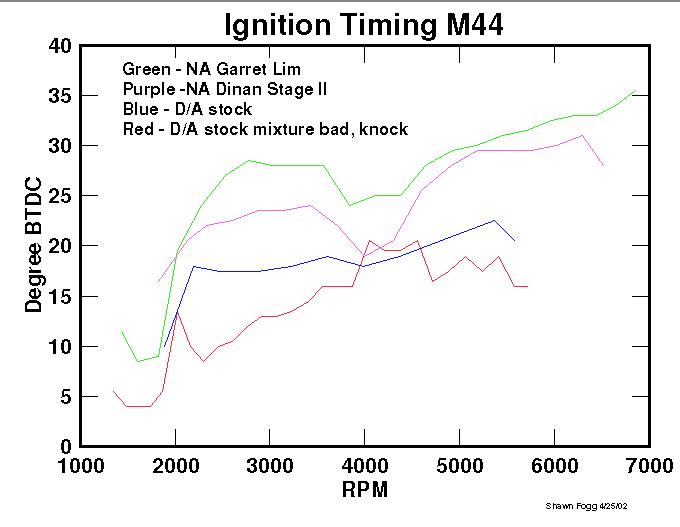

In my case I found I was a little leaner then I should be above about

4k or so. By using OBDII scanning software I found that it wasn't causing

problems in first and second gear but in third gear (and above) I was getting

timing retard. I could sort of feel this in that the engine wasn't as smooth

and it felt like the power was dropping off fairly rapidly at 80+ mph.

Which it was because of the timing retard. My O2 voltages were dropping

from over 0.9v down to 0.7v range up high. Getting the fueling proper cured

my timing retard and the engine now pulls very hard up there. It is also

MUCH safer for the engine.

The red trace is my car with the D/A in place with my WOT mixture not rich enough. The blue trace is with the mixture tuned better with the PCIII and the D/A AFPR. Still isn't perfect but considerably better and I will be tuning it further when I remove the AFPR and go to the larger injectors. The purple and green traces are from naturally aspirated 1.9ls with Dinan Stage II software and Garret Lim's software. All that additional ignition advance would be a bad idea on a forced induction engine. I believe the dips on both of them are not knock but are programmed in to make the DISA transition smoother.

Anyone with a forced induction engine that wants their mixture+timing tested is welcome to stop by. See the Garage Invite.